A century before Apollo astronauts walked on the Moon, science fiction told the public of a future with outposts on the Moon and orbiting high above the Earth. In the decades that followed, these earliest space station concepts evolved into orbital platforms that could launch manned missions to the Moon and Mars. After its inception, NASA picked up where visionaries left off, dabbling in space stations of varying layouts and capabilities before building the International Space Station that orbits the Earth today.

Austrian Herman Noordung's 1929 concept for a toroidal space station that would generate artificial gravity by spinning.

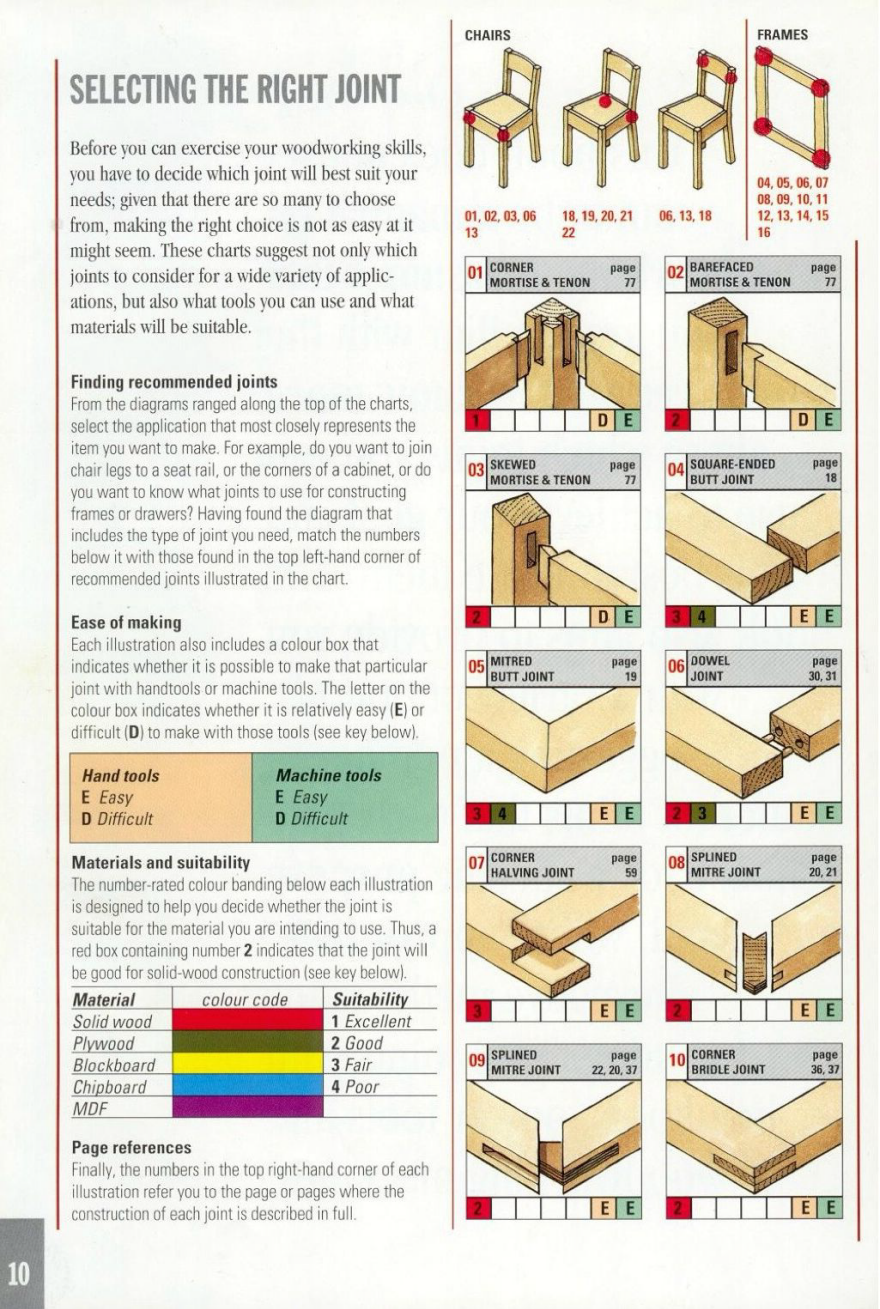

Earliest Concepts in Science Fiction

Between October 1869 and February of 1870, readers of the Atlantic Monthly were introduced to the idea of living off the Earth through Edward Everett Hale’s science fiction story, "The Brick Moon.” Hale’s story tells of a 200-foot diameter brick sphere designed to orbit the Earth as a navigational aid for ships. But the brick moon is accidentally put into orbit with people on board. Halle followed this story with a sequel, ‘Life in the Brick Moon,’ wherein the characters find ways to survive in their new home. Not only do they live in the artificial satellite, they communicate with the Earth turning the brick moon into a communications satellite.

The term “space station” was coined more than fifty years later by Romanian rocket pioneer Hermann Oberth. Writing in 1923, he envisioned a platform orbiting the Earth that would serve as a starting point for missions to the Moon and Mars. His idea was shared by Austrian Herman Noordung who, in 1928, published a blue print for an orbital outpost composed of multiple modules each with its own unique function.

Both Oberth and Noordung imagined their space stations would be launched by massive rockets, and an ocean away American engineer Robert Goddard was taking major strides towards developing these rockets. Goddard was among the first to experiment successfully with liquid propulsion, harnessing a reaction far more powerful than the black powder rockets that were prevalent at the time. And he wasn’t the only one. In Germany, an amateur rocket group called the Verein für Raumschiffahrt (Society for Space Travel) was also having moderate success with liquid propelled rocket. In 1932, one member of the VfR, Wernher von Braun, was handpicked by the German Army to continue his work, developing liquid rockets for the military.

Von Braun's Space Station

Von Braun presents his toroidal space station on Walt Disney's Tomorrowland TV show.

Military funding from the Reich before and during the Second World War brought rocketry to maturity, and by the war’s end von Braun’s team had a functioning rocket on their hands with the V-2. The technology was picked up by both American and Soviet scientists, but the bulk of leftover hardware and key team members migrated to the United States in 1945, including von Braun who added "spaceflight popularizer” to his resume before long.

Through collaborations with Collier’s Magazine and Walt Disney on the Tomorrowland TV series, von Braun brought his vision of a wheel-shaped space station to the public. This orbital platform would be an Earth observation post, a microgravity laboratory, as well as an observatory. It would also be a starting point for missions to the Moon and Mars, serving as a cornerstone in man’s exploration of the inner solar system.

NASA explored inflatable toroidal space stations in the early 1960s. Most of these concepts were studied out of the Langley laboratory.

Space Stations for the New Space Agency

These futuristic space station concepts started inching towards reality in 1958. NASA was created to manage all spaceflight programs with the overarching goal of getting an astronaut in space before the Soviet Union lunched a cosmonaut. Anticipating putting the first man in space, NASA was already considering a space station as its second program in 1959, something that would help the agency learn to live and work in space before serving as a jumping off point for manned missions to the Moon. But Yuri Gagarin beat an American astronaut into orbit, derailing NASA’s long-range plan. President John Kennedy considered all possible next steps for America in space and determined that a mission to the Moon would be a better show of technological dominance than a space station.

NASA was laser focused on the Moon landing goal throughout the 1960s, but the a space station was never truly off the drawing board. Spurred on by Apollo’s high funding level and the growing national interest in spaceflight, an orbital outpost was again seriously considered in 1964 NASA’s main post-Apollo program. Four years later, it was officially on the books.

This 1969 concept was for a 100-man space station called Space Base. It was intended as a laboratory and living space that could double as a home port for nuclear-powered space tugs that could ferry astronauts to the Moon.

In 1969, NASA proposed a 100-man space station called Space Base. The idea was to build a platform that would serve as a laboratory for scientific and industry-sponsored microgravity experiments as well as a home port for nuclear-powered space tugs to ferry astronauts to and from an outpost on the Moon. Scheduled for orbital assembly to be completed by 1975, it didn’t take NASA long to realize that the cost of using expendable rockets (like the Saturn family that launched Apollo to the Moon) to both build and supply Space Base would exceed the construction cost of the station. The only way the project wouldn’t be a loss for NASA would be to build and supply it with a reusable vehicle, a sort of shuttle to ferry supplies and astronauts to Space Base over multiple missions. This became the Space Transportation System, more colloquially known as the space shuttle.

But a space shuttle was in the future. For the moment, NASA had an excess Apollo hardware from three cancelled lunar missions and opted to turn it into a short-term space station program called Skylab. The station itself was made form a repurposed S-IVB upper stage and launched on the last Saturn V in May of 1973. In the year that followed, Skylab hosted three crews, ultimately proving that humans can not only live and work in space, they can be instrumental in large-scale orbital construction efforts as well. The first Skylab crew performed emergency spacewalks to successfully free a jammed solar array, effectively saving the station.

Skylab was America's first space station. Launched in 1973, it hosted three crews before it was abandoned in orbit and left to fall to Earth. It reentered the atmosphere in 1979.

Skylab was never intended to be a long-term space station; it wasn’t designed to be resupplied, refuelled, or boosted into a higher orbit. After the last crew left in February of 1974, the station was abandoned and its orbit was left to decay. NASA briefly considered using a space shuttle orbiter to boost it into a higher orbit and revisit the station, but increased solar activity had expanded the Earth’s atmosphere, the fringes of which were dragging on the station more than expected. NASA simply couldn't have a shuttle ready in time. Skylab reentered the Earth’s atmosphere over western Australia in July of 1979.

The Beginnings of a Real Space Station

As the Skylab program unfolded, NASA forged ahead with the reusable space shuttle that would facilitate building and maintaining a long-lasting space station. But the project as initially conceived by the agency proved too ambitious for its shrinking post-Apollo budget. The economic, political, social, and cultural landscape in the early 1970s wasn’t conducive to another program on the same scale as Apollo. The agency was forced to choose between an orbital outpost or a the vehicle needed to build it. The latter won, and the space station was put on hold while NASA developed its space shuttle.

With the station’s future uncertain, NASA began exploring the potential of working with international partners to defray its cost. In 1973, the United States and Europe formally entered into a partnership that would see the European Space Agency supply mini laboratory modules called Spacelabs to NASA. These small units were designed to launch in the shuttle’s massive payload bay and serve as experiment facility for up to three weeks in orbit, a proof of concept for a later station. The first Spacelab reached orbit in 1983 as part of the payload of STS-9.

The Dual Keel Space Station

NASA's dual keel space station layout.

From Dream to Reality

In his State of the Union Address on January 25, 1984, President Ronald Reagan called for NASA to collaborate with international partners to build a space station within a decade. It was the political backing the space station program desperately needed. With congressional support and a formal presidential mandate in place, the agency established the Space Station Program Office in April and issued requests for proposals to industry leaders that fall. Two years later, Japan and Europe signed on to contribute modules and Canada agreed to supply a manipulator arm. The station was emerging from these early design stages with a dual keel arrangement with a central truss to hold the main living and working quarters as well as solar arrays.

But setbacks seemed to trump every step forward. One problem was the steadily rising cost. NASA’s original projection of $8 billion for three separate facilities — the main living space and two automated laboratory platforms — proved ambitiously low. The Challenger disaster also took its toll on the space station. The loss of seven astronauts raised safety concerns that ended with the decision to give astronauts on board the space station some escape system. This forced design changes that in turn increased the station’s weight.

This 1991 concept art shows space station Freedom in orbit around the Earth. Freedom was the first true space station concept NASA tried to get off the ground. It was designed to be the launch point for missions to the Moon and Mars in addition to an orbital living and work space.

The solution was to replace the dual keel arrangement with a single truss design and to make the laboratory modules smaller overall. This new design was finalized in 1987. In 1988, Reagan gave the station a name: Freedom.

Bush Puts NASA on a Path to Mars.

In July of 1989, just six months after taking office, President George Bush attempted to have his own “Kennedy moment.” In a speech commemorating the 20th anniversary of Apollo 11 mission, he called for the United States to return men to the Moon and send astronauts on to Mars within three decades. And he endorsed space station Freedom as the cornerstone of this long-range effort. The plan was, roughly, a tripartite one. Immediately in the 1990s construction of space station Freedom was to be NASA’s main endeavour. Lunar missions were slated to resume in the early 21st century with the establishment of a lunar base for long term exploration. These two steps would lay the groundwork for a manned mission to Mars as early as the late 2010s. The ultimate goal was a permanent outpost on the red planet.

Bush’s call for a Mars landing yielded a 90-day study to solidify the program’s prospective timeline, goals, and cost. The idea was for Freedom to evolve alongside the effort to land men on Mars. It would serve as an orbital test bed where NASA would iron out the technologies needed to support long-duration deep space missions, and with crews staying on board for up to six months at a time it would be a way for the agency to learn about human survival in space in the relative safety of low Earth orbit.

This concept art from 1989 shows the ferry spacecraft used to take astronauts between a space station and the Moon, and possibly Mars.

The subsequent phase of lunar missions would rely heavily on Freedom. The crew, vehicles, and supplies would launch to the space station where they would load into a transfer vehicle. That transfer vehicle would then travel to low lunar orbit where it would meet an excursion vehicle that would either be waiting in a parking orbit or would launch from the surface to meet the arriving spacecraft. The excursion module would then take the crew to the lunar surface while the transfer vehicle would return to Freedom for maintenance and resupply. The crew could stay on the Moon for as long as a year, serviced by that same transfer vehicle ferrying between Freedom and the Moon. A similar arrangement was planned for missions to Mars.

From Freedom to ISS

As the 1990s dawned, Freedom was getting increasingly heavy and complicated with new requirements like the provision for spacewalks to support in-orbit assembly. Freedom’s cost rose to $38.3 billion, a figure that now included the shuttle launches but was still a far cry from the original $8 billion estimate. In 1993, President Bill Clinton called for the station to be redesigned once again in an attempt to lower the cost and bring in more international partners. Three redesigned station were put forth, and the proposal called Alpha was chosen by the White House.

This 1995 concept shows space station Alpha, an early version of what eventually became the International Space Station.

Alpha used 75 percent of the hardware from Freedom, and before long Russia offered pieces of its unflown Mir 2 space station to lower the overall cost. This new station developed as one that promised to be far more capable than Freedom. In the course of the redefinition process, Alpha took on the moniker “International Space Station.” NASA’s Johnson Space Centre became lead centre behind the program, and Boeing signed on as prime contractor.

The ISS program kicked off with the Shuttle-Mir program, the first cooperation between the United States and Russia since 1975’s Apollo-Soyuz Test Project. In February of 1994, cosmonaut Sergei Krikalev became the first Russian astronaut to fly on a shuttle with the STS-60 crew. A year later, the orbiter Discovery rendezvoused with Mir during the STS-63 mission. In March of 1995, U.S. astronaut Dr. Norman Thagard launched with two cosmonauts aboard Soyuz-TM 21 for a three month stay on Mir. At the end of the mission, the orbiter Atlantis docked with Mir to collect the crew and bring them home. In November of 1995, the orbiter Atlantis launched on STS-74 and delivered a Russian-built Docking Module to Mir marking the first time a module was added to a working space station in orbit. These shuttle-Mir missions gave NASA astronauts their first exposure to long-duration spaceflight since Skylab and also taught both nations valuable lessons in working together and building a multi-module station in space.

The ISS began taking shape in earnest in 1998. On November 20, the Zarya Control Module launched on a Russian Proton rocket. It was the first piece of the station, the battery power and fuel storage unit onto which later modules were added. The Unity node followed in December, and in May of 1999 the shuttle orbiter Discovery fitted the station with logistics and stocked it full of supplies. Four assembly missions in May, July, September, and October of 2000 saw addition of the Zvezda Service Module as well as installation of the Z1-Truss, a third pressurized mating adapter, and a Ku-band antenna. These missions also delivered supplies and performed maintenance on the Station. It was finally ready for a human crew.

On October 30, 2000, Expedition 1 launched on a Soyuz rocket and docked with the International Space Station. The crew of Yuri P. Gidzenko, William M. Shepherd, and Sergei K. Krikalev became the first to live and work on board the orbiting outpost. Another thirty-two assembly missions completed the ISS, bringing the dream of a space station to life nearly a century and a half after Hale’s story captured imaginations.

Sources: Report of the 90-Day Study on Human Exploration of the Moon and Mars; A History of US Space Stations; NASA's Space Station Evolution and Current Status; ISS assembly timeline; Hale's "The Brick Moon"; "Tomorrowland" TV episodes (part 1 is here, and you can find the rest on You Tube or buy it on Amazon).

NSFW

NSFW [This unattributed image has been floating around the web. If anyone knows the provenance, please let us know in the comments so that we can properly attribute it.]

[This unattributed image has been floating around the web. If anyone knows the provenance, please let us know in the comments so that we can properly attribute it.]  [This unattributed image has been floating around the web. If anyone knows the provenance, please let us know in the comments so that we can properly attribute it.]

[This unattributed image has been floating around the web. If anyone knows the provenance, please let us know in the comments so that we can properly attribute it.]  [This unattributed image has been floating around the web. If anyone knows the provenance, please let us know in the comments so that we can properly attribute it.]

[This unattributed image has been floating around the web. If anyone knows the provenance, please let us know in the comments so that we can properly attribute it.]  [This unattributed image has been floating around the web. If anyone knows the provenance, please let us know in the comments so that we can properly attribute it.]

[This unattributed image has been floating around the web. If anyone knows the provenance, please let us know in the comments so that we can properly attribute it.]  Via

Via  By

By  By

By  By

By  By

By  By

By

Nicholas Felton

Nicholas Felton The cover of Felton's

The cover of Felton's  Inside the 2014 report. Felton began the project in 2005, weaving together information about his personal activities—where he’s traveled, the books he’s read, how much sleep he’s gotten, and much more—into dense, beautiful infographics.

Inside the 2014 report. Felton began the project in 2005, weaving together information about his personal activities—where he’s traveled, the books he’s read, how much sleep he’s gotten, and much more—into dense, beautiful infographics. From the

From the  The contents of the

The contents of the  Felton's desk in his Brooklyn studio

Felton's desk in his Brooklyn studio By delivering a few randomly timed surveys each day, Reporter attempts to measure and visualize subtle aspects of users' lives.

By delivering a few randomly timed surveys each day, Reporter attempts to measure and visualize subtle aspects of users' lives. Felton’s labels for the winemaker Between Five Bells include seasonal temperature and rainfall data.

Felton’s labels for the winemaker Between Five Bells include seasonal temperature and rainfall data. For Wired, Felton visualized ten years of Wikipedia data.

For Wired, Felton visualized ten years of Wikipedia data.

The fully-enclosed evovelo mö promises to 'combine conventional car comfort with the benefits of a bicycle.'

The fully-enclosed evovelo mö promises to 'combine conventional car comfort with the benefits of a bicycle.'