The future of Cyanogenmod

http://syfycity.tumblr.com

Inomata says:

Inomata says:I overheard that the land of the former French Embassy in Japan had been French until October 2009; that it was to become Japanese for the following fifty years, and then be returned to France. This concept made me think of hermit crabs, which change their shells.The same piece of land is peacefully transferred from one country to the other. These kinds of things take place without our being aware of it. On the other hand, similar events are not unrelated to us as individuals. For example acquiring nationality, moving, and migration.The hermit crabs wearing the shelters I built for them, which imitate the architecture of various countries, appeared to be crossing various national borders. Though the body of the hermit crab is the same, according to the shell it is wearing, its appearance changes completely. It’s as if they were asking, “Who are you?”

I'm not sure what's more enraging—the casual racial profiling or the presumption of guilty-until-proven-innocent—but it's getting hard to deny that the racists are in the driving seat of policy at the Home Office these days.

The racism is utterly, dismally, predictable when times are bad—frightened, stressed people with no economic security look around for someone to blame, and they can be very easily manipulated into blaming others. It's important also to remember that the 1930s were populated by people coming to terms with rapid technological change-induced future shock, and looking for certainty in the face of the future. Today, we have similar levels of future shock, largely social in nature: thanks to the internet we can't ignore other people whose views we find repugnant.

But racism isn't the key issue here. The real question we should be asking is not "what" but "why".

I have a new speculative hypothesis to stand alongside the Martian invasion and the bad dream. It is this: the over-arching reason for the clamp-down on dissent, migration, and freedom of expression, and the concurrent emphasis on security in the developed world, constitutes the visible expression of a pre-emptive counter-revolution.

The fuse for a revolution was lit by the global financial crisis of 2007/08, in a process that looked alarmingly close to triggering the Crisis of Capitalism (a hypothesized event which is associated with an ideology to which the current political elite of the USA and EU are for the most part highly allergic, for anyone aged over 50 spent their formative years under the bipolar tension of the Cold War). It sputtered briefly in the west in the form of the Occupy and related movements, but truly caught fire in 2009 with the failed Green revolution and in 2010-11 with the Arab spring—which were inflamed by the spike in global food prices caused by capital fleeing into commodities in the wake of the banking crisis. Meanwhile, the imposition of disaster capitalism in the west (as a purported "solution" to the debt-based spending bubbles various western governments embarked on during the boom years of the 1990s-2007) inflamed popular tensions in those countries, with results like this (undirected rioting) that never adhered to any political direction, but nevertheless terrified the ruling elite, leading to their retaliation via draconian punishments.

The wave of revolutions has so far been contained within the Arab world (a part of the globe which—I don't think this is any kind of coincidence at all—is suddenly becoming much less important to the energy geopolitics of the west, with the switch to fracking and renewables now under way). The policy of pre-emptive counter-revolution, facilitated by the imposition of the global internet panopticon, has clamped the lid down tight.

So, in summary: I believe what we're seeing is a move towards the global imposition of a police state in the developed world, leveraging the xenophobia that naturally emerges during insecure times, by a ruling elite who are themselves feeling threatened by a spectre. Controls on movement, freedom of association, and speech are all key tools in the classic police state's arsenal. What's new about this cycle is that the police state machinery is imposed locally, within national boundaries, but applies everywhere: the economic system it is intended to protect is transnational and unconstrained. Which is why even places that were largely exempt during the cold war are having a common police state agenda quietly imposed. There is to be no refuge, other than destabilized "failed states" where the conditions of life make a police state look utopian in comparison.

This system has emerged organically, from the bottom up, and is not the result of any conspiracy; it's just individuals and groups moving to protect their shareholdings in the Martian invaders, by creating an environment that is safe for the hive intelligences to operate in.

As to how I feel about this ...

I'm middle-aged and comfortable and have no great love for revolutions, even though I'd say that the imposition of a global police state deserves a place high on the list of complaints weighty enough to legitimize one. But revolutions almost invariably go bad. A few, like the Velvet revolution, turn out all right in the end; but many more provide opportunities for the vilest dregs of humanity to run amok. Only when the post-revolutionary society stabilizes and the convulsions subside do we get to see whether or not we're better off: and even if we are, that's scant comfort for the bereaved relatives of those who died in the process. As I said, I'm middle-aged, fat, and have health issues: don't look for me on the barricades. If it happens, I'll be over here wringing my hands and writing communiques calling for less smashing of skulls. Because? Fuck every cause that ends in murder and children crying.

Yanko Design features the work of Tony Grigorian, who has produced a set of instructions for recycling the varied and fascinating components in washing machines into intriguing and sometimes beautiful furniture. Scrap washing-machines are a treasure-trove of weird-shaped pieces with striking characteristics; when correctly combined, the pieces they make are both arresting and immediately identifiable as having begun their lives as washing machines. Grigorian's instructions are a good jumping-off point for making your own pieces.

Yanko Design features the work of Tony Grigorian, who has produced a set of instructions for recycling the varied and fascinating components in washing machines into intriguing and sometimes beautiful furniture. Scrap washing-machines are a treasure-trove of weird-shaped pieces with striking characteristics; when correctly combined, the pieces they make are both arresting and immediately identifiable as having begun their lives as washing machines. Grigorian's instructions are a good jumping-off point for making your own pieces.

I Used to be a Washing Machine ![]()

The Distributed Flight Array is an experimental project from ETH Zurich; it's a set of 3D-printed hexagonal rotors with magnets on their edges; they automatically join up with one another, sense and compute the aerodynamic properties of their current configuration, and cooperate to fly together.

The system is designed around a central propeller which provides thrust for the structure. Surrounding it are three omni-directional wheels that let the bots get into position with each other on the ground while magnets embedded in the frame provide a connection. A gyroscope provides positional information to an on-board microprocessor while an infrared sensor feeds information about altitude to the system. Pins allow the collected bots to communicate this real-time data between each other and adjust their individual thrusts to keep the combined unit stable. Despite the sensitive nature of the electronics, when a flight is over, the bots disengage midair and fall safely to the ground where the process can begin anew.Individual units can only propel themselves spastically around a room, but when joined the DFA modules can create traditional quadcopters, more advanced decacopters, and their most impressive applications are atypical and asymmetrical arrays that defy traditional aeronautic aesthetics. These odd combos often produce interesting flight patterns — in one configuration where the bots are aligned linearly, the construct appears to flap as the opposite ends try to reach equilibrium.

...Next steps for the project will be removing the last vestiges of human control—currently a motion-capture system or an operator using a joystick has to provide a small amount of feedback to keep the system from drifting away. The hope is that the DFA becomes completely autonomous and increasingly versatile. “What I would love to see is in-flight reconfiguration,” says Oung. “Which I think is certainly possible with the current system.”

Watch: Autonomous Robots Self-Assemble and Take Flight as One [Joseph Flaherty/Wired]

(via /.) ![]()

Yesterday, we posted a tech memoir by Steven Ashley about the slow rise of 3D printing — from sci-fi fantasy, to toy, to creator of real tools. Towards the end of the piece, Ashley mentions how GE is starting manufacture aircraft engine parts using 3D printers. Here's the excerpt:

Rows of industrial 3D-printing units in plants will soon be fabricating turbine engine parts—fuel nozzles—from cobalt-chromium alloy powders. Each one of GE’s new LEAP jet engine will contain nineteen of the fuel nozzles, which are up to 25 percent lighter and five-times more durable than traditionally manufactured fuel nozzles. In airplanes cutting weight saves fuel. The LEAP engine has already amassed more than 4,500 orders, so between it and the new GE9X engine, the corporation could end up making as many as 100,000 additive manufactured components by 2020.

In the picture above, you can see one of those fuel nozzles, in all its 3D-printed glory.

It's also worth noting, Ashley says, that 3D printing your airplane parts can allow you to design pieces that cut out unnecessary weight in ways that other manufacturing processes can't. In this next photo, you'll see two versions of the same bracket — the one on the left was 3D printed. It's full of holes and has rounded, rather than square, corners, both of which represent the reduction of unneeded material that you couldn't easily do away with in any other way.

‘Female Robbery’ by The Neighbourhood

I downloaded this in a mixtape and immediately became obsessed with it, in a multiple-times-per-day-repeat-listening sort of way. I cannot understand why.

Adobe’s evangelist Renaun, created a video to explain how to use Chrome’s serial API to talk with an Arduino board as well as receive data from it. You just need to run this sketch file on your board and then run the code in Chrome. Watch the video below to hear Renaun commenting the code!

JakkynThe brass ring did come out well. Much smoother than the stainless direct printing process, though I generally prefer silver-colored jewelry to gold.

“I’m so sad it’s Friday. I wish it was Monday already!” Said No one in history ever. Time to enjoy some of this week’s featured printed items.

Gabe sculpted a ‘Genese Character’ in Mudbox and Softimage (both from Autodesk). The statue is about 8 inch tall, printed in polyamide and has an awesome spikey texture.

The Carapace ring from Noah Beasley is an alien ouroboros ring in gold plated polished brass.

Andreas Rittershofer from http://3ddecodetails.com designs great models to detail the roofs of your model railroad structures! Check out the amazing paint job he did on the cooling unit and air conduct in 1:160 (N-scale). Prime gray shows once more why it is an amazing material for all kinds of scale models.

And last but not least, hailing from Australia, we have the CXB sheep wagon from Marbelup Models. Not just the wagon was printed (prime gray), also the sheep load (alumide). Both the wagon and the sheep (90 of them) were painted to add a realistic texture.

Don’t forget to put your own designs in the gallery to show your work to the world.

Photos by Simon Markhof

Photos by Simon Markhof

With the help aerospace engineers at EADS, Somerset, UK-based Charge Bikes have refined and expanded their 3D-printed dropout production since we first came across them last August, as evidenced by a new vid from last week. However, German IDer Ralf Holleis does them one better with the VRZ 2 Track bicycle, developed under the VORWaeRTZ moniker. (Further details on Holleis's practice are scant; from what I can determine, he's connected to the equally mysterious designlab coburg.)

| archive - contact - sexy exciting merchandise - cute - search - about | |||

| dinosaur comics returns monday! this weekend i'll be at TEDxUofT talking about TIME TRAVEL, maybe i will see you there? :o

|

|||

| ← previous | May 16th, 2013 | next | |

|

May 16th, 2013: I saw the new Star Trek movie last night and it has the XCV 300 in it! It's my favourite Enterprise after the Enterprice C. Anyway that's all I wanted to say One year ago today: SECRETS OF THE BANKING PROFESSION – Ryan

| |||

metahaven - The Cloud, the State, and the Stack: Metahaven in Conversation with Benjamin Bratton

Lets say you’ve come up with a brilliant idea for some shiny new piece of hardware. You brush up your coding chops, scratch out a design, and set out to build a prototype.

First, you’ll need a programmable chip to act as the brain. Because of the relatively gentle learning curve and friendly community, you go with the Arduino. The problem: your hardware idea requires WiFi.

Until now, that’s actually been a pretty complicated issue.

It’s not that Arduinos couldn’t do WiFi before — it’s just always been a bit of a pain. You had two main options, neither of them perfect:

At this weekend’s Maker Faire, the company announced the Arduino Yún (with Yún being Chinese for “cloud” and English for “Yeah, most people are probably just going to type Yun without the fancy ú.”), the first official Arduino to come with WiFi functionality built-in out of the box.

At its core, the Yún is actually part traditional Arduino and part Linux system. The Arduino handles all of the functionality it traditionally would — running your code, reading from sensors, etc — while an itty-bitty Linux-powered chip acts as both a WiFi receiver and transmitter, handling all of the HTTP gruntwork needed to get your hardware project online. Plus: you can reprogram the Arduino Yún over WiFi, no USB cable required.

Lost in geek-speak here? Wondering what all of this means to you? Basically, one of the most popular platforms for DIY hardware projects has just made it a whole lot easier to get said projects connected to the Internet. Want a coffee maker that starts brewing 30 minutes before Google Calendar says you’ve got guests coming over? Sure, why not. Want an alarm that automatically donates money from your PayPal when you hit the snooze button? Totally doable.

Just this week, a project focused on building a high-quality, WiFi-enabled, Arduino-compatible board raised over $300,000 on Kickstarter. That’s over 30x their initial goal of $10,000, and they’ve still got nearly 2 weeks left. There’s definitely a lot of interest in such a thing.

The Yún should start shipping at the end of June, and will cost about $69. That’s about twice the cost of the WiFi-less Arduinos available today, but still significantly cheaper (and more compact) than buying both an Arduino and an add-on WiFi-shield.

JakkynThis is the new greatest thing ever!

Mataerial by Petr Novikov, Saša Joki?, Joris Laarman Studio and IAAC is a 3D printing robot that instead of building an object layer by layer, draws forms from any surface out into thin air.

Working in the same manner as the "3D printing pen" except instead of your shaky hand trying to make a recognizable shape from an ooze of hot plastic cooled by a fan, this process uses two thermosetting polymers which set when combined by a precision robot actually 3D Printing in space. The team also state that CMYK colors can/could be combined in the same manner to create full color 3D printing using the same method. The same process could of course be used at a much smaller scale and theoretically multiple robots could 3D print different materials simultaneously onto any surface such as a conductive material and a non conductive material to create electrical pathways. This is definitely a technology to watch and hopefully their patent application is not so restrictive as to restrict its potential.

Mataerial is the result of the collaborative research between Petr Novikov, Saša Joki? from the Institute for Advanced Architecture of Catalonia (IAAC) and Joris Laarman Studio. IAAC tutors representing Open Thesis Fabrication Program provided their advice and professional expertise. During the course of the research we developed a brand new digital fabrication method and a working prototype that can open a door to a number of practical applications. The method that we call Anti-gravity Object Modeling has a patent-pending status.

I am a Canadian that studied industrial design. It’s not surprising that I often got strange looks when I told people about my thesis project to redesign America’s voting system. The reason is simple though - I find America to be an amazing and fascinating nation and also like exploring the diverse applications of industrial design thinking. The 2012 election was the first time I experienced an American election first hand. I found it to be absolutely exciting and intriguing. I loved it.

However, I also realized how broken the election process in the US was. There is a complete lack of cohesion and poor design creates inefficiency and inaccuracies. A great nation like the US deserves better, and America Elect is my take.

The total time spent on the project is approximately 14 weeks with about 70% of time dedicated to research. The insight of over 600 Americans were collected and analyzed for areas that need most improvement. The voting process of Canada, Sweden, Japan and Estonia were also studied for inspiration and insight. One of the biggest areas of emphasis was understanding why things are the way they are and how to maintain “Americanness” in my own solution.

Note

I am not claiming that my interview/survey results are 100% representative America. For instance, though similar, the voter turnout figure in my own survey is higher than the true national average. This information was collected primarily to validate my own research.

One of the goals of this project was to create a solution that is neutral and can be agreed upon by both the Democrats and Republicans. As another point of reference, I created a spider chart to compare the opposing parties' responses.

Above are some interesting responses to the question; “Why do you or do you not vote?”

When I started this project, I was certain that an internet voting system needed to be created. As I began my research, it became clear that internet voting simply cannot exist with current security technologies. Above is a SWOT (strengths, weaknesses, opportunities, threats) analysis of internet voting. The security of voting systems is a national defense issue and convenience does not outweigh the accuracy of votes.

Above are some ballots and a registration form from various counties/states. Horrendous design is rampant, creating confusion for voters and at times, alters the votes of citizens by causing incorrectly marked ballots. It’s embarrassing.

Above is a small sample of some of the process. The biggest challenge was trying to capture the essence of America graphically. I then discovered that the best option is to allow photography to speak for itself. A box (similar to a ballot check box) is then used to frame the photo and typography is added. This solution also enables easy differentiation between states through use of different imagery.

The first thing I have created is America Elect, an independent, non-partisan agency that designs and conducts federal elections and referendums. The agency is an expansion of the EAC (Election Assistance Commission) established in 2002 to develop guidance for voters. America Elect’s mission is to simplify the election process, promote voting, and develop secure and convenient voting systems. I personally believe that the security of voting systems is a national defense issue and proposed that America Elect be funded using a cut of the defense budget.

One of my goals was to create a more representative voting system than The Electoral College. However, I also did not want to create something that completely removes power from less dense states. My solution is The Electoral Sector, a voting system based on congressional district boundaries. Each district, or sector, is given a vote and these votes directly elect the President without the need of electors. The result is a more accurate representation of America with a reduction of the two-party effect.

The first step to voting is registration. Unregistered voters receive a Voter Registration booklet in the mail that provides a streamlined registration process. America Elect also provides a nation-wide online registration process for the first time.

When voting season arrives, voters are sent a Voter Invitation Package that includes a Voter’s Guide, Express Ballot and promotional pins. The Voter’s Guide has “Ikea-like” instructions and makes voting easy to understand. The voter then completes the Express Ballot, signs and dates, and mails it using the included prepaid envelope. Voting is now completely mail-in with polling stations reserved for voters with accessibility requirements.

America Elect could also offer a website with a variety of helpful services like registration and requests for replacement ballots. The website is also an ideal location for providing accessibility services like audio voters guides.

America Elect includes an effort to promote voting in America. The “I Voted” sticker is a great tradition but isn’t effective because it promotes voting when it’s too late. Voters now receive Let’s Make History pins with their Voter Invitation Package, well before the deadline for ballots. I have also created posters, billboards and a 30 second advertisement for the campaign.

The new ballot offers a cleaner design that’s easier to read. The grey backdrop helps navigate the voters’ eyes and all the type flows in one direction. All-caps type has been removed as it's not ideal for legibility. Language has also been made more direct and to the point. Voters now mark their ballot with an X, a more simple solution than the convoluted “completing the arrow”, something that doesn’t exist outside of American ballots.

The existing voter’s guides are complex and don’t make much sense. The new experience uses design to make a complex process simple.

The Voter’s Guide has also been written with simple language. The Government and its agencies have a tendency to overcomplicate, which results in loss of interest from the public. I have also created a Chinese version of the voting materials as a visual reference.

Friendliness was also key to the design of America Elect. The Voter’s Guide provides assistance with language that is friendly and helpful.

Instead of calling the America Elect ballot a “mail-in ballot” or “official ballot”, it is called an “Express Ballot”. Even simple changes in wording can communicate ease, promoting more people to vote.

America Elect has been designed down to the smallest detail.

Here is every page for the complete experience.

My friend Jonathan Ward and the rest of the team at Otherfab have posted their new CNC milling machine, the Othermill, to KickStarter. This is a robust, low-cost machine for milling circuit boards, wax molds, wood, aluminum and more. The machine is made from high density polyethylene with an ingenious snap-fit mechanism that’s strong, reversible, and easy-to-assemble (although the machines will come fully assembled). There are lots of other clever features to ensure good alignment, minimal / non-existent slop, and quiet / robust performance. The working area is 5.5 x 4.5 x 1.4″ and the machine itself is only 10 inches cubed.

This is a great tool for milling your own circuit boards, something that’s done a lot in How to Make (Almost) Anything and at the MIT Media Lab and Center for Bits and Atoms generally. It handles relatively fine-pitched components (down to 1/64″ or even 0.010″ between traces) and is great for doing arbitrary shapes and cut outs. Here are some examples from the Othermill KickStarter page.

Jonathan has a long history of making milling machines, and I’m excited to see them get out into the world.

Find out more or support the project on KickStarter.

1993 A.D.

Can’t find the source, seems to be imgur fodder…

*It’s a press release. And a heck of a video, too.

“To celebrate Earth Day, Google Earth today announced it now supports Leap Motion as part of its desktop application (which works on PC, Mac and Linux). Google Earth has been downloaded more than 1 Billion times, and now the free and professional versions support input from Leap Motion’s innovative 3-D motion control technology.

A video preview of Leap Motion + Google Earth: http://youtu.be/RebX7YEn3GQ

“Leap Motion’s developer community of 10,000+ will be the first able to #LeapInto Google Earth, but it will be available to any Leap Motion user when we ship soon.

“We’re excited to share the news about this amazing application of our technology, as it allows for a new, more immersive experience. We also have a YouTube playlist collecting submitted videos of people (first our dev community and Leap Motion employees) sharing their #LeapInto Google Earth explorations.

“Quotes from Michael Buckwald, co-founder and CEO, Leap Motion:

“Our mission at Leap Motion is to provide a fundamentally better computing experience that frees people to create and explore the digital world in new ways. Google Earth combined with Leap Motion’s 3-D, touch-free technology feels so incredibly immersive – people feel connected to the world in a new and compelling way.”

“Today, our community of more than 10,000 developers around the world are the first people able to experience Google Earth through Leap Motion. When we ship soon, we’re excited to see what new explorations people leap into.”

Questions for Google: Email press@google.com

“Happy Earth Day!”

Sayaka Ganz creates marvelous animal sculptures from plastic crap she picks up at thrift stores. "Sayaka Ganz: Reclaimed Creations" (via Juxtapoz)

Sayaka Ganz creates marvelous animal sculptures from plastic crap she picks up at thrift stores. "Sayaka Ganz: Reclaimed Creations" (via Juxtapoz)

|

There’s nothing like a little electronic art to get the heart pumpin’. This doesn’t do that, but it does make your eyes jitter and cause the people in the coffee shop to stop talking bad about their friends for a few minutes. Michael Chang is a designer, programmer, game creator and a master of three.js, an open-source javascript 3D library, and Processing. His generative machines use three.js and a bit of his own hacks to construct, explode and colorize all sorts of machine-like geometry, creating what’s likely to be the coolest 3D procedural exploded machine diagram art you’ve seen this week.

The generative machines project was created by Michael as a Chrome experiment for Google IO. The images are beautiful, but the experience is even better. Projected on a wall and put to the sound of Wolfgang Gartner, Justice or the the like and you’ve got yourself a AV face feast to keep your senses happy for a few more hours. The inspiration is mechanical and every shape is procedurally generated.

The idea of a procedural exploding view diagram was very attractive to me. It had all the right elements: a bunch of techy looking mechanical shapes, diagrammatic, and all of these lines criss crossing everywhere as if to suggest motion of a kind that automatically assembles.

It wasn’t enough that I simply had rivets and slots coming together, I also wanted to make an overall structure that looked as if, when assembled, became a machine that forms a whole that was more than the sum of its parts.

This got me thinking about creating procedural shapes that I can cut up. My first exploration into this was creating a one dimensional exploding axis, where elements can fly forward or back, and adding a radial dimension where elements could be chopped up and exploded outwards.

And this is where it starts getting amazing…

The highest level was the skeleton, which would be a procedurally generated series of nodes…The strategy I ended up with was to generate a “spine” from which radial and branching skeletons would emerge. After the skeleton was decided on, a function traverses each joint and generates the “meat” on the bones, called “assemblies”.

The next layer is what I call assemblies. Each assembly lives on a single joint length in the skeleton. They exist as functions that are hand tailored to procedurally generate something recognizable, such as a jet engine or a battery compartment (I wasn’t too focused on realism at this point). The assemblies get information about the joint length, and where the next joint is, but that’s about it. Inside each assembly are some randomized parameters, and sometimes conditions based on length, so each assembly will look slightly different based on initial conditions.

Finally at the ‘lowest’ level were components. These were essentially recyclable geometry generating tools I would use in each assembly to create the recognizable pieces, such as struts, lattices, wires, etc. For what it’s worth these were pretty quickly hacked up and not really meant to be reusable for the future, but they accomplished their job admirably.

I won’t copy and paste every bit of the article, hop over to read the rest, but the excerpt above is just phenomenally futuristic sounding if you apply it to 3D modeling or constructing a model generatively from say, a parts list or bill of materials. Yeah, some cad software developers are playing with this and it’s not likely to be as visually eye-jittering, but a little UX panache wouldn’t hurt–it’s all part of my “MAKE PRODUCT DEVELOPMENT PRETTY” campaign.

So, check out the entire story on how Michael went through the process. He links to code, provides examples and tells you in detail what worked to finally develop the visuals in the generative machines he set out to create. I particularly enjoy when he reveals that his inspiration for the colors came from Mirror’s Edge and that each machine uses a random color palette created from a distributive sampling of each image. Beautiful.

Hat tip to infovis aficionado and Ph.D. Lynn Cherny for sending this in, oh so long ago.

JakkynFavela chic grinderwear

When high-school students get bored it can only lead to one thing… The design of a new, fully-articulating prosthetic leg made from bike parts that cost a fraction of a professionally manufactured leg. Parker Owen’s Saturday night boredom turned into looking at picture on the Internet… pictures of bicycle schematics and prosthetic design. Now, he has a provisional patent on the prosthetic leg, plans to make more and the goal to take several with him on a summer mission trip to Honduras where he’ll manufacture 20-30 additional legs over the week-long trip.

Parker is a student at the Alabama School of Mathematics and Science (ASMS). In the video below, Parker says, “I don’t really see this as the next big thing or the greatest invention in the world.” Well Parker. We’re pretty sure that the thousands of people who are going to benefit from this in the future will think so. The first leg prototype took him 5 hours to build. It uses the seat and seat post for the foot, ankle and lower leg with intertubes acting as the tendon and muscles. He’s built adjustablility into the design with both the tension and length able to accommodate the wearer.

Of course, this prosthetic, as it is, would have a tough time meeting the Class I medical device regulations in the United States, but it certainly would be possible for Parker to create a similar design using similar materials in order to register the device through the FDA. If anyone has been through this process or can provide some insight for him, please contact him through ASMS.

Thanks to Jason Foutch for sending this in!

Source/Images: Alabama.com

While debate rages in the U.S. over drone surveillance of its citizens, drones were pressed into service over London on Saturday for a less contentious purpose: To promote the upcoming Star Trek movie. Ars Electronica Futurelab, an Austria-based media art lab, collaborated with German quadrocopter manufacturer Ascending Technologies to give Paramount Pictures publicity via "spaxel."

Thirty autonomous, LED-equipped "Hummingbird" drones took to London's evening skies, then self-assembled into the Star Trek logo, which then rotated as a whole. If that sounds simple, it sure ain't; Futurelab's software has to keep the drones from crashing into each other while they take off and find their positions, and the matter was complicated by both wind and snow, the former affecting the navigation and the latter affecting the drone-to-drone communication. Nevertheless, they were able to pull it off:

(more...) |

|

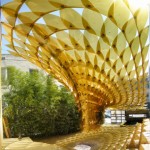

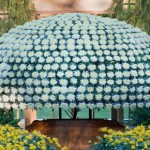

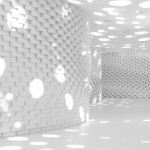

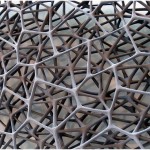

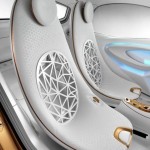

The interplay between the organic and the geometric is at the heart of the Geo-Organic category. This trend is very closely related to Geometric Form/Organic Matrix, but inverts the relationship between form and structure. Whereas the previous theme employs highly rational, primitive, geometric forms supported by a chaotic cellular internal lattice (like the Water Cube), the Organic Form/Geometric Matrix trend uses flowing, curving, organic volumes constructed from an internal matrix of repeating rigid geometric modules. The type of module can be highly varied (2×4 wood planks, felt spheres, ceramic discs, sheets of translucent plastic, etc.), but is always some basic geometrically-described shape. Also, the repeating internal pattern can range from fairly chaotic to orderly repetition. Overall forms tend to be either subtly or acutely curvaceous, from blob-like volumes to dynamic flowing sheets, but never straight, angular, or rigid. The overall impression of this trend is one of liveliness, motion, flow, and a juxtaposition of both simplicity and complexity. These forms seem alive. Inspired by the natural world from veins in leaves to the structure within bones, designers have lately used this association (especially in Architecture and Furniture) to create dynamic visual statements. Due to the internal complexity of these structures, manufacturing/assembly can be a challenge. In mimicking what nature does so easily, we have to hand-assemble each matrix module, or as in the case of Trabecula invent new production technologies like 3D-printing to create them. But if these production complexities can be overcome, imagine the possibilities of seeing this trend within the Automotive or Product categories…anyone up for the challenge? We’re looking at you.