Shared posts

A Forsaken Touch by Tristin-Vitriol

Two Thoughts

As Damien Walter noted recently on twitter, some time between 1995 and 2010, the human species began to develop functional telepathy. (Actually, the first sign of this became real on October 29th, 1969, but exponential growth from a small base takes a long time to become noticeable.) We now have over a billion human beings on the internet, and so many devices that the IPv4 address space is saturated: within the next decade we can expect multiple new satellite internet constellations (such as OneWeb and rivals) to bring pervasive internet access to the globe. Smartphones are pushing down into the sub-$50 space where they're affordable even by those living just at the global poverty threshold (and the decline in global poverty over the past decade is working away at the other end). It no longer looks implausible to suggest that almost everybody will be online by 2025.

A side-effect of this process is that we're becoming used to a constant background roar—the global id in full throat, blasting us with the prejudices, rumors, superstitions, bigotry, and (less obviously) love and passion of the entire human species. Everyone being online means that anyone can in principle yell in your ear at any time, be it encouragement or rape and death threats.

So far we seem to have handled the telepathy thing relatively well. It hasn't provoked a nuclear war, or even very many social media targeting drone strikes. It has provoked total panic among authoritarian political leaders, with its concomitant ability to facilitate flash mobs, and a much quieter level of paranoia and near-panic among national security organizations, but compared with the consequences of the development of the printing press it's pretty benign. However, we're still in the early days.

More significantly: Markets. Some would say we're entering the post-capitalist era; certainly it's interesting to speculate on the effects universal functional telepathy (lies and all) are going to have on how we handle business. The internet disintermediates supply chains, but there's a catch: you have to be able to find your customers, or your root supplier, before you can cut out the middle-men. Currently we're seeing a land-rush by new middle-men trying to stake out their position as the Sultans of Search: Amazon and eBay were first wave, but the likes of Uber or AirBNB are now trying to occupy the equivalent space in vertically segmented business niches (personal transport and rented short-let accommodation respectively). The current 2015 cruel joke is that to identify a new Silicon Valley start-up opportunity you just have to figure out what your mom no longer does for you now you've moved out of her basement and productize it. But that's not going to last forever.

One of the performance drivers of an internet startup is the ability to automate and replicate a service that formerly scaled up by adding human bodies—travel agents are replaced by Hipmunk or Kayak, for example. But a side-effect of this is that there's a constant pressure to deliver the same automated search results for less money, on fewer processor cores. It's a race to the bottom and it ends when search becomes free at the point of delivery. Which might, to a first order, sound like a recipe for "sponsored search results" and biased results, but when you can open multiple browser tabs and do meta-comparison across product comparison websites for virtually zero cost, such lying informational lacunae will be found out fast.

Ultimately most of those middle-men are doomed: they simply can't add enough value to stay viable as information arbitrage brokers in a telepathic world.

So where do we go from there? (Is telepathy compatible with the continued existence of capitalism?)

Design of the Week: 2-string Piezoelectric Violin

This week’s selection is Monad Studio’s incredible 2-string Piezoelectric Violin.

Monad studio is a group...

Hydrographic 3D Print Painting?

Wired reports on a potential method of coloring complex 3D prints: hydrographic painting. But is it really feasible?...

The PIRX one Debuts

PIRX 3D has launched the PIRX 1.0, a very interesting consumer 3D printer.

We first encountered PIRX at last fall’s London 3D Printshow, where we were impressed with their experimental color 3D printing prototype. That capability does not appear to be included in this announcement, as the “one” is a monocolor 3D printer.

The attractive filament extruding machine has some impressive statistics. In its generous 210 x 270 x 210 build volume, it can print layers as small as 0.03mm (30 microns). A wide variety of materials are supported due to the included heated print surface; PLA, Nylon, PS, Laywood, Ninjaflex, ABS and more can work in this machine.

According to PIRX 3D, the machine can print at “high speed”. Although we’re not sure of the exact speeds, the machine is built from “high-quality parts, custom made linear guides and optical Z end stops”, so it’s likely this is true. Regardless, the prints look pretty darn good, as you can see here.

The key feature of the PIRX 1.0 is automatic bed leveling. Here’s how it works: before print commences, a sensor checks the bed height at several positions. From these measurements, the software understands the tilt of the bed, even if only slightly tilted. Then the first layer print is dynamically adjusted by raising and lowering the bed very slightly to compensate for the tilt as the extruder moves about. This is a feature that should be included on every 3D printer.

What’s missing? Just the color printing we saw in the prototype. But before you can do that, you must sell the “basic” machine. It won’t be surprising if they announce a color feature on future machines, but for now, you can order a PIRX 1.0 for only €1200 (USD$1360).

Via PIRX 3D

colorFabb Announces Carbon Fiber Filament

Netherlands-based colorFabb introduced an incredibly powerful new 3D printer filament today, based on carbon fiber.

The new material, cryptically named colorFabb XT-CF20, is a co-polyester based on their custom Amphora polymer. Amphora, jointly developed by colorFabb and Eastman Chemicals, is a new polymer specifically designed for use in 3D printers. Now they’re leveraging this substance by adding carbon fiber.

Like other hybrid specialty filaments, the XT-CF20 is a mix of Amphora and in this case, “no less than 20%” carbon fiber material. It prints in the same manner as other 3D printer filaments, yet produces objects with significantly improved engineering performance. Yes, they’re stronger.

colorFabb indicates the new material is “twice as stiff as PLA” yet is not brittle. Like other Amphora-based materials, XT-CF20 is very low odor during printing.

The strength of the new material permits extended uses, particularly for parts experiencing mechanical stress. Here we see an RC car developed with parts printed in XT-CF20. Note the heavy stress components, which might easily break with other materials. Certainly you can break XT-CF20, but it will take more effort to do so as compared to previous colorFabb filaments.

Appearance-wise, XT-CF20 has a flat, matte black finish and is offered only in this color. That’s not really a drawback as the use of this new material is likely for mechanical parts where color is not so important.

Any drawbacks? Only one, according to colorFabb, who say XT-CF20 is somewhat more abrasive than other filaments, and thus may introduce additional wear effects on your hot end. Specifically, they recommend using a stainless steel or hardened copper hot end instead of the more commonly found brass hot ends.

Pricing? Expect a premium price for this material: €50 (USD$57) gets you a spool of 750g. Available now for preorder at their online shop; shipping expected in late February.

Via colorFabb

A Shot In The Dark

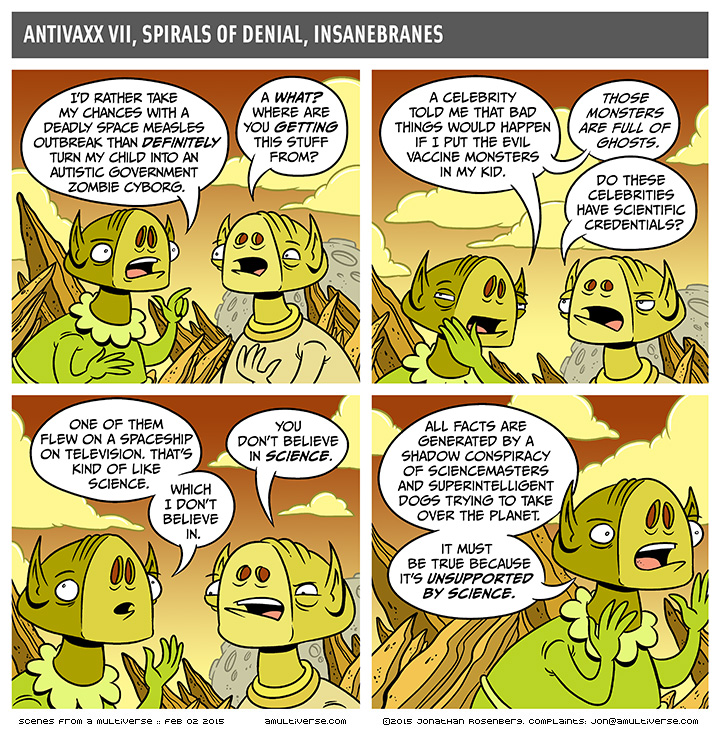

Nine out of ten doctors agree, anti-vaxxers are morons. The tenth doctor also agrees. So does the eleventh, twelfth and the War Doctor. The Valeyard could not be reached for comment.

We are now selling these brand new phone cases! Designs include Bunnies Monolith, Cornelius Snarlington, Dungeon Divers and more. Check ‘em out.

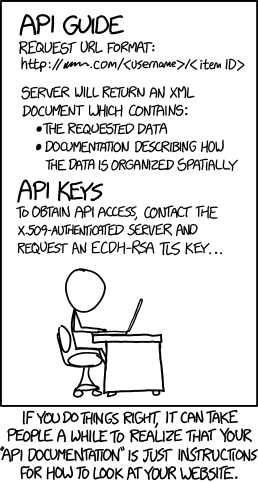

API

JakkynThis is relevant to both my interests, and day to day life the past week...

ISIS targets the Pilots of the Airwar

JakkynI highly recommend reading everything on Global Guerrillas from the past couple months or so, this is John Robb at his best. He's been attempting to cover sustainable living for awhile now on his other blogs, but comes across as annoyingly repetitive (even though he has a lot of good points there). However, this is his element, and he seems to be one of the very few people actually Paying Attention in this area.

ISIS executed (burned to death) a Jordanian pilot this week. To maximize the impact of the event, ISIS released a slickly produced video of the event. The video was a "complete trial" that included >>

- An interview with the pilot (the "testimony").

- Some footage of western airplanes blowing things up (the "crime").

- The brutal execution of the pilot (the "punishment").

Censorship as a Non-Strategy?

What was the west's response? Censorship. Here's a full version of the video I've found (it won't last long). The US government is putting on Web hosts around the world to remove videos like this. So, it will be censored and removed soon. Censorship isn't a smart strategy.

- Censorship turns the video into "secret knowledge." Accessing it in defiance of dictates of a state adds to its allure, particularly for young people targeted by ISIS.

- Censorship displays a complete misunderstanding of how online discussion works. IF it had been allowed online, it would have ignited tens of thousands of discussions required to turn this into learning event.

- Censorship gives the impression that the West is weak and in retreat. The danger is that weakness invites aggression.

ISIS targets the Air War

The ex CIA/DoD guys on the major media networks, didn't have much to say about the event. Here's some more thinking:

- Media: ISIS is mindlessly brutal. JR: a more insightful analysis shows that these brutal punishments (Christians would call them "old testament" punishments) are taken from the pages of the Quran. They are specifically selected to recruit Muslims schooled in scriptural literalism by pointing out that modernist Islam ignores scripture when inconvenient. This punishment was specifically selected for its brutality because the "crime" was push button bombing (the US claims this air war has killed ~6,000 members of ISIS).

- Media: This execution was unjustified. The pilot was innocent. JR: The video spent quite a bit of time justifying the execution. In parallel, ISIS tied the morality of airstrikes to the morality of suicide bombing by offering to trade the pilot for some prisoners in Jordan. That was successful, Jordan confirmed this connection by immediately executing these prisoners in retaliation for the death of the pilot.

- Media: ISIS wants to intimidate the west. JR: Not really. ISIS had a more specific target in mind. They are trying to intimidate the pilots of the air campaign. At the end of the video, ISIS offers 100 Gold Dinars (~$18,000) for the heads of specifically named Jordanian pilots they consider criminals. By personalizing this, they have just pierced the veil of anonymity that protects the pilots that make push button air warfare possible.

PS> Fox video has the full video up.

GG Update - January 2, 2015

Some items of interest:

- The random darknet shopper. A bot with a budget to randomly purchase items on darknet sites. It had a budget of $100 in bitcoins to spend every week. Here's what it bought. BTW, the law is fairly squishy on bots that break the law. Here's a Hungarian passport it bought. --> This is an automated way to grief a specific individual (CEO, Judge, etc.).

-

Nanodegrees. An attempt by Udacity to unbundle education so that you can learn just what you need. This would only be of value if going to college was about education. It's not. Innovation like this might be possible within new economic networks (likely tied together by blockchains to prevent spoofing/scams).

-

Swatting. Is there an upside to the militarization of the US police system? There is if you want to attack a person using something called swatting. Swatting is a fake call to 911 that prompts the police to send SWAT to take down the target's address. Swatting has been around for a looong while but it's only recently become a national epidemic (we don't now how bad it is because the FBI doesn't track statistics on it = who could have guessed that?).

-

Stampedes. Crowds are more likely to turn deadly when trying to enter a venue than exit it. Why? One reason is that entry is often restricted to collect tickets/etc or control timing (think Walmart on black Friday). Exit options are often more fluid and open. Another reason is that crowds often surge forward when there's reason to believe they are missing an opportunity (as we saw in the Shanghai stampede on new years night that killed 36 people).

*Google “Material Design”...

*Google “Material Design” principles.

http://www.google.com/design/spec/material-design/introduction.html#introduction-goals

wetheurban: DESIGN: Totally Accurate LED Lamp Mimics The...

DESIGN: Totally Accurate LED Lamp Mimics The Moon

Japanese design practice Nosinger has created the LED light ‘Moon’.

prostheticknowledge: Face Hacking Follow-up demo of the Omote...

Face Hacking

Follow-up demo of the Omote real-time facial projection mapping project by nobumichiasai featuring the creators - video embedded below:

SMAP×SMAP(FUJI-TV) 2014/12/22 ON AIR

REAL-TIME FACE TRACKING & 3D PROJECTION MAPPING

FACES ARE HACKED BY SOMEONE AND ARE GOING TO BE REWRITTEN FACE.nobumichiasai has a Tumblr blog here

Crazy New 3D Printing Filaments Available

We noticed several rather unusual 3D printing filaments are now available for you to try out.

M3D offers what they call “Chameleon Filament”. Why so? Because it actually changes color! They offer several different Chameleon filaments:

- Blue 15C

- Rose Red 30C

- Green 30C

- Orange 45C

The number indicates the color-changing property:

- 15C changes to blue when its temperature is less than 15C (59F) (However, they say it can become permanently white if exposed to UV light - so don’t put these prints outside!

- 30C changes to black when colder than 30C (86F)

- 45C changes to white when warmer than 45C (113F)

These color-changing filaments could provoke some very interesting models. Imagine a dual extruder able to insert some of this filament into an object - you’d have temperature-sensitive sections, which could be buttons, touch detectors or temperature warning indicators.

Another unusual pair of filaments is now provided by ProtoPasta: Stainless Steel PLA & Magnetic Iron PLA. The stainless steel filament can be polished to a shiny finish, or as they explain, “left unfinished for a cast metal appearance”.

Their Magnetic Iron PLA is truly magnetic when printed, but that’s not all. The iron can oxidize, producing a rusty surface. Thus, this filament offers two unusual properties.

We’re most intrigued with the magnetic property, however. A dual extruder setup could enable printing doors with magnetic clamps to hold them closed. Small amounts of magnetic material could enable easy assembly of multi-part objects. Simple lids would never slip off. The possibilities are wide.

These developments show there’s no end in sight for filament materials. By mixing particles into standard polymers, filament can be produced that has the properties of wood, metal or other substances. You can now choose filament not only from a wide selection of colors, but also filaments with many different properties.

Via M3D and ProtoPasta

NASA considers possibilities for manned mission to Venus

"NASA’s Systems Analysis and Concepts Directorate has issued a report outlining a possible way for humans to visit Venus, rather than Mars—by hovering in the atmosphere instead of landing on the surface. The hovering vehicle, which they call a High Altitude Venus Operational Concept (HAVOC), "

HAVOC

!!!

A stunning look at the cliffs of comet 67P/Churyumov-Gerasimenko

JakkynPrior the Rosetta mission, my concept of comets never included the idea that there would be features like cliffs on one...

Deep neural network rivals primate brain in object recognition | KurzweilAI

JakkynWoot! Go Ai researchers and neuroscientists!

"A new study from MIT neuroscientists has found that for the first time, one of the latest generation of “deep neural networks” matches the ability of the primate brain to recognize objects during a brief glance."

Hogan McLaughlin Spring // Summer 15

Hogan McLaughlin Spring // Summer 15

Pre-orders are currently open for a brief window with an expected holiday shipment.

Hogan McLaughlin Spring // Summer 15

Pre-orders are currently open for a brief window with an expected holiday shipment.

Corporate Disruption using Snowden Style Moral Warfare

In light of he Sony hack, here's some earlier GG thinking on disrupting corporations.

The most interesting aspect of the Sony hack?

As we anticipated, nobody cared. Not the public. Not the government.

In fact, most people made fun of the victims and the information released was widely reprinted.

Why did wasn't there a response? Three reasons:

- the attack was bloodless and it wasn't aimed directly at the decaying infrastructure of the nation-state,

- the wealthy victims don't evoke any empathy with a jaded/abused middle class, and

- the ability of the nation-state to provide security is diminishing very rapidly (as Snowden showed, they can't even protect themselves).

What does this attack mean?

- Moral warfare against corporate targets works. Snowden showed it worked against the NSA. It is working against Sony due to the mendacity and simple nastiness of the personalities involved. As a result, Sony, and everyone associated with Sony will suffer economically. The company is now toxic, further everyone damaged by the hack is going to sue it. In fact, the damage from these leaks may be severe enough to tank the company.

- This is survivable for the attackers. The lack of punishment for this attack in addition to the earlier example seen with Snowden, shows that it's possible to conduct this type of attack repeatedly without evoking a 9/11 level manhunt.

- We're going to see this again and again and again. JP Morgan was hacked at the root level last year. All of their e-mails and data may end up being bought and used in a moral war against the company in the future. We may also see some innovation. For example, it can be focused on a single individual with ease. I suspect an attack like this could destroy the net worth of a billionaire if done in the correct way. Not only that, most people would probably laugh at the victim's descent if the right target is chosen.

*Well, there it went. A rehearsal, with an empty capsule, for...

*Well, there it went. A rehearsal, with an empty capsule, for an Indian manned space flight. The launch was successful.

http://scroll.in/article/695451/India’s-latest-space-rocket-is-no-‘jugaad’

Design of the Week: Kinematics Dress

This week’s selection is Nervous Systems’ startling Kinematics Dress.

The problem of 3D printed fashion for many years has been the lack of sufficiently flexible materials. Thus, the fashion you’d often see involved “hard” objects, such as jewelry, belt buckles, head adornments or various rigid attachments. These items have also been far too small to make up an entire fashion outfit, as the build volumes of 3D printers are typically far smaller than most humans. But recently we’ve seen several folks experimenting with a new approach to flexibility: linkages.

We first saw this approach in London at Digits2Widgets lab, where they had created 3D prints with almost fabric-like qualities. However, it was only a small section. Now we see the brains at Nervous Systems, Jessica Rosenkrantz and Jesse Louis-Rosenberg, have used a similar technique to produce an entire dress with appropriate flexibility.

Rosenkrantz explains:

We’ve created a large object from a 3D scan of a person that is much larger than a 3D printer. And then we’ve used a physics simulation to fold up the dress into a small form that can fit inside the machine for fabrication. So the entire idea of this hinges on when we take it out of the machine it can unfold into a dress.

That’s the key: enabling printing of an entire fashion piece within a limited print volume. That requires flexibility, but so does the dress itself when worn. Creating a dynamic “chain-mail” like object does the trick.

And does it have flexibility! Please watch the video to see the natural motion provided by this ingenious approach.

As you’ll see in the video, it was uncertain whether the experiment would succeed. Could you really 3D print a folded dress? Would it unfold without breaking? Fortunately, the experiment was a complete success.

The work was produced at Shapeways’ Brooklyn factory, where their EOS machines printed the dress in nylon. The dress has now transferred to New York City’s MOMA for permanent display.

We believe this is a milestone in 3D print design, as it now opens up a broad range of possibilities for fabric-like fashion design. Nervous System were one of the first to produce computer-generated 3D printable jewelry some years ago; it looks like they’ve broken through another barrier this week.

Via Shapeways

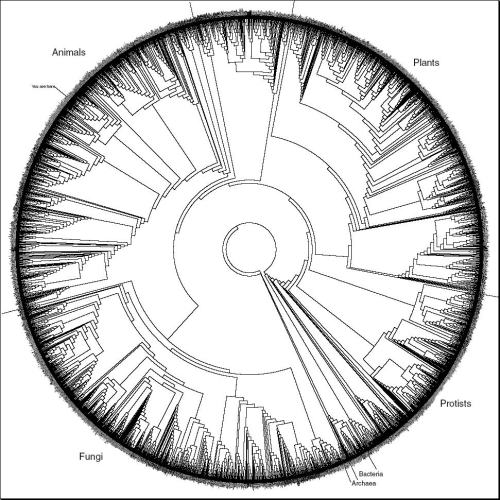

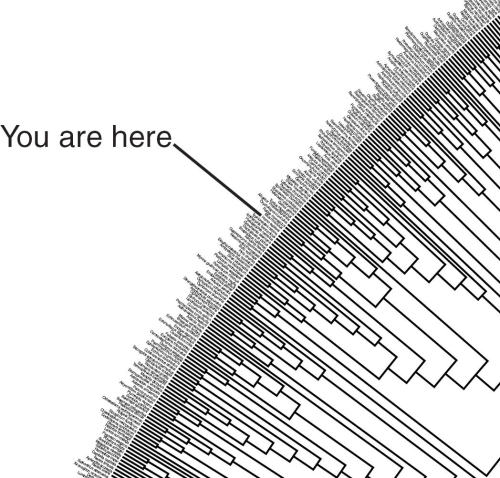

scienceisbeauty: Cladogenetic tree of representatives of all...

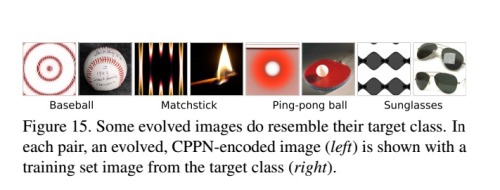

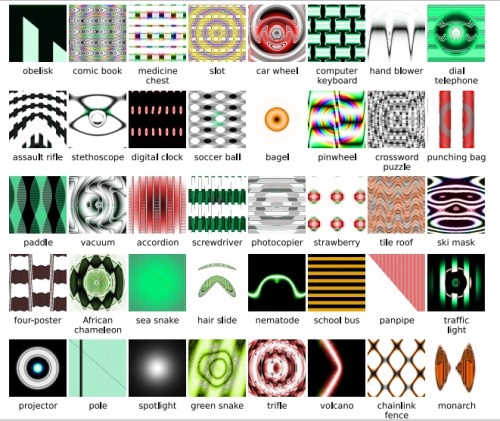

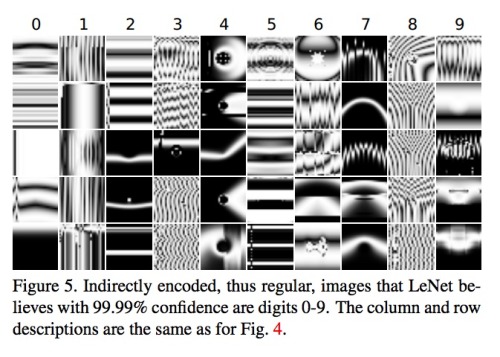

*Optical illusions for computer vision...

*Optical illusions for computer vision systems.

http://www.newscientist.com/article/dn26691-optical-illusions-fool-computers-into-seeing-things.html

![goat-mcase[1]](http://amultiverse.com/wp-content/uploads/2015/01/goat-mcase1-450x346.jpg)